9260 High Silicone Spring Steel 6 x 45 x 1200mm

AU $40.00

9260 High Silicone Spring Steel with dimensions of 6 x 45 x 1200 mm. It offers outstanding corrosion resistance, hardness, toughness, and strength.

- Description

- Additional information

- Reviews (0)

Description

9260 is a high-silicone, spring steel. It offers outstanding corrosion resistance, hardness, toughness, and strength. 9260 is machinable in the annealed condition, and is weldable by most common methods except oxyacetylene welding. 9260 can be found in a wide variety of applications, most of which demand resistance to bending and failures.

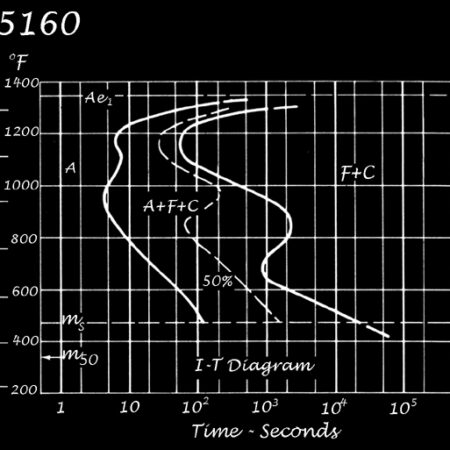

Recommended Working Sequence For 5160

Forging: Heat to 2200 °F (1205 °C) maximum, and do not forge after forging stock has dropped below approximately 1600 °F (870 °C)

Normalizing: Heat to 1650 °F (900 °C) and cool in still air.

Annealing: To produce a structure of coarse to fine spheroidite, parts should be austenitized at 1400ºF (760ºC) and cooled to 1300ºF (705º) at a rate of 10ºF/hr., or alternately cooled to 1225ºF (660ºC) and held for 10 hours as an iso-anneal.

Hardening: Austenitize at 1525-1580 °F (830-860 °C) and water quench.

Tempering: As-quenched hardness as high as 63 HRC. After quenching, reheat to the temperature required to provide the desired hardness.

Additional information

| Weight | 2.6 kg |

|---|---|

| Dimensions | 120 × 4.5 × 0.6 cm |

Be the first to review “9260 High Silicone Spring Steel 6 x 45 x 1200mm”

You must be logged in to post a review.

Reviews

There are no reviews yet.