52100 High Carbon Bearing Steel (2.38 x 63 x 900 mm)

AU $62.00

52100 High Carbon Bearing Steel – 2.38 x 63 x 900 mm

- Description

- Additional information

- Reviews (0)

Description

52100 is the steel used to make ball bearings and its reputation for use in high performance knives is legendary. Whether it is a carbon steel kitchen knife or hunter, if you are after a high performance cutter 52100 is well worth your consideration.

A chromium alloy steel, 52100 is excellent to use from forging to finishing. It has great toughness and durability on its own or forge-welded to other steels, such as 410 or 416. Our 52100 comes pickled and annealed.

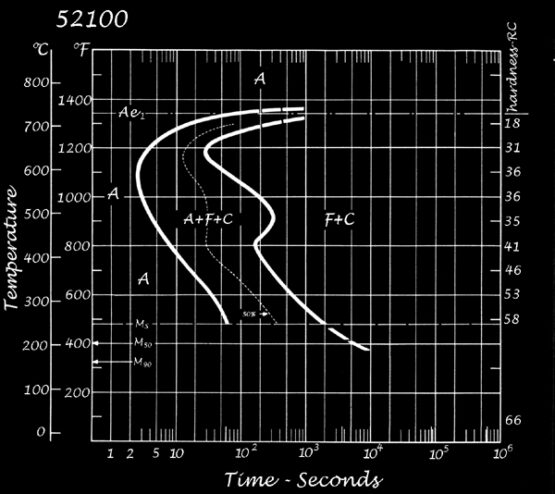

Recommended Working Sequence For 52100

Forging: Heat to 2100 °F (1150 °C) maximum, and do not forge after temperature of the forging stock has dropped below approximately 1700 °F (925 °C)

Normalizing: Heat to 1625 °F (885 °C) and cool in still air.

Annealing: For a predominately spheroidized structure which is generally desired for machining, heat to 1460 °F (795 °C) and cool rapidly to 1380 °F (750 °C), then continue cooling to 1250 °F (675 °C) at a rate not exceeding 10 °F (6 °C) per hour; or as an alternative technique, heat to 1460 °F (795 °C), cool rapidly to 1275 °F (690 °C) and hold for 16 hours.

Grinding or Machining

Hardening: Austenitize from 1475°F to 1550 °F (845 °C) and quench in g quench or equivalent oil.

Tempering: As-quenched hardness as high as 66 HRC. After quenching, parts should be tempered as soon as they have uniformly reached near ambient temperature. Hold at 392 °F (200 °C) For 2 2 hour cycles

Additional information

| Weight | 1.65 kg |

|---|---|

| Dimensions | 122 × 6.5 × 0.24 cm |

Be the first to review “52100 High Carbon Bearing Steel (2.38 x 63 x 900 mm)”

You must be logged in to post a review.

Reviews

There are no reviews yet.